- Home

- Used Equipment

- Equipment Packages

- Small Tractors

- All Product Lines

- Departments

- Company Profile

- Parts Online

- Contact Us

- John Deere Specials - Save Some Green

1575

TerrainCut™ Front Mower

- 7-Iron™ PRO Side Discharge or Fastback™ Rear Discharge Deck

- Diesel Engine

- Integrated ComfortCab

- Compatible with select front blade, snow blower and broom attachments

- Build Your Own

-

Get a Quote

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Send to a Friend

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

- View Product Brochure (English)

- View Product Brochure (Spanish)

-

Share

Features

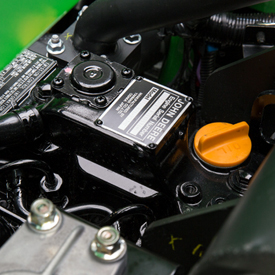

Diesel engine has high-quality features to minimize operating cost

Hood open for access to engine

Hood open for access to engine

3-cylinder, liquid-cooled diesel engine

3-cylinder, liquid-cooled diesel engine

The 1500 Series TerrainCut™ Front Mowers are powered by liquid-cooled, 3-cylinder diesel engines.

These engines feature low levels of exhaust and emissions, reduced noise levels, and excellent fuel economy. They also meet the necessary Environmental Protection Agency (EPA) Tier 4 emissions requirements.

The 1570, 1575, 1580, and 1585 models are biodiesel compatible from the factory up to B20. The 1550 model requires an optional kit to be compatible with B20 biodiesel fuel.

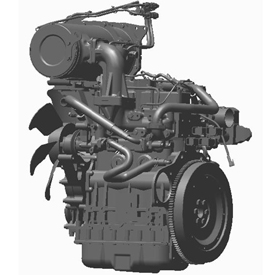

Engine drawing for 1570, 1575, 1580, and 1585

Engine drawing for 1570, 1575, 1580, and 1585

| 1550 | 1570, 1575, 1580, 1585 | |

| Fuel | Diesel (optional kit permits B20 compatibility) | Diesel (B20 compatible) |

| Gross power at maximum rpm | 25 hp (18.4 kW), PS | 37.4 hp (27.5 kW), PS |

| Displacement | 77 cu in. (1.262 L) | 100.2 cu in. (1.642 L) |

Key features of the engine include:

- Economical cast-in block cylinder design for good cooling and long life

- Indirect fuel injection (1550)

- Direct fuel injection (1570, 1575, 1580, 1585)

- Injects fuel directly on top of pistons for more efficient combustion

- Delivers more horsepower per gallon of fuel

- Improves starting

- Develops more horsepower per gallon of fuel and improves starting

- Aluminum alloy pistons with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by gas and noise from the piston slap

- Higher top rings on the piston and a thinner head gasket greatly reduce the volume of unburned waste gases and increase combustion efficiency

- Timing gears and injector drive gears utilize helical profile gears to help lower engine noise; gear teeth have a newly designed roll-off profile, giving almost no clash, no noise, and no backlash

- Fuel filter with replaceable element

- Full-pressure intake manifold provides quick starts in temperatures down to 0°F (-18°C) (optional engine coolant heater attachment assists starting under more extreme conditions)

- Auto-bleed fuel system – there is no need to prime the system if the tractor runs out of fuel; the system self-primes the injection pump, lines, and injectors, providing fast fuel recovery

- Key start and shutoff eliminates fuel shut-off knob; electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Enclosed engine compartment to keep out debris and lower sound levels

- Sealed radiator compartment to keep trash and debris on outside of hood

- Excellent torque for plenty of lugging power when operating in tough mowing conditions

- Full-pressure lubrication for positive lubrication, even when operating on slopes

- Dual-element, dry-type, replaceable air cleaner completely sealed for effective cleaning

- 90 percent to 95 percent of dirt ejected before it reaches the paper element

- Secondary safety element for additional filtering

- Progressive-type air restriction indicator to let operator know when the filter needs servicing

- Automotive-type alternator for plenty of charge to the battery and power for accessories

- 75 amp for open-station models

- 95 amp for ComfortCab models

- Automatic initiation of air heater for easier cold-weather starting

- Automotive-sensing system tells operator when engine is ready to start

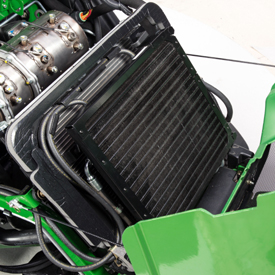

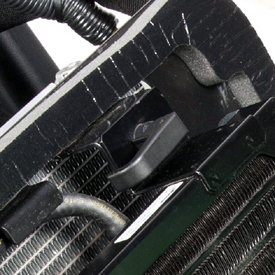

Rear-mounted radiators

Rear-mounted radiators (1550, 1570, 1580)

Rear-mounted radiators (1550, 1570, 1580)

Rear-mounted radiators and air conditioner condenser (1575, 1585)

Rear-mounted radiators and air conditioner condenser (1575, 1585)

Fuel tank is large capacity with convenient gauge for maximum uptime

Fuel tank

Fuel tank

Fuel gauge (shown on 1585)

Fuel gauge (shown on 1585)

Fuel tank features:

- 16-U.S. gal. (60.6-L) capacity provides a 10-hour run time.

- Top draw provides clean fuel.

- Fuel indicator is conveniently located.

Mower decks for TerrainCut™ Front Mowers match a wide variety of needs

Since 1998 the John Deere 7-Iron™ mower deck has demonstrated commercial quality, performance, and durability. The 7-Iron PRO, FastBack™, and FastBack PRO mower decks deliver an even higher-quality cut in even more diverse conditions.

1580 TerrainCut Front Mower with 72-in. (183-cm) FastBack PRO Mower Deck

1580 TerrainCut Front Mower with 72-in. (183-cm) FastBack PRO Mower Deck

1575 TerrainCut Front Mower with 72-in. (183-cm) 7-Iron PRO Mower Deck

1575 TerrainCut Front Mower with 72-in. (183-cm) 7-Iron PRO Mower Deck

TerrainCut Front Mower Compatibility

| Mower Deck | 1550 | 1570 | 1575 | 1580 | 1585 |

| 60-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck | X | X | X* | X* | X* |

| 62-in. (157-cm) FastBack Rear-Discharge Mower Deck | X | X | X | X | X |

| 72-in. (183-cm) 7-Iron PRO Side-Discharge Mower Deck | X | X | X | X | X |

| 72-in. (183-cm) FastBack PRO Rear-Discharge Mower Deck | X | X | X | X | X |

Rear weights (UC13263) are required based on machine configuration. Must also order TCB10303, rear weight mounting bracket.

*Mower deck offset for trimming capability. Vehicle track width is 2 in. (5.1 cm) wider on the discharge side of deck. This may cause the tire to drive over uncut grass on discharge side of deck.

NOTE: These mower decks will not retrofit to F900 Series or F1145 Front Mowers.

Rotate for Service (RFS™)

Mower deck showing RFS feature

Mower deck showing RFS feature

Rotate for Service (RFS) feature provides access for cleaning and maintenance of the mower decks:

-

The rotation angle will vary depending on deck size and power unit tire size.

-

No tools are required to access belts.

-

The underside of the mower deck is easy to access.

-

Easy on/off design simplifies installing and removing mower decks.

-

Top, greaseable spindles can be accessed without removing belt covers.

The Rotate for Service position also reduces the length of the machine for trailering.

Certification

TerrainCut Front Mowers comply with ANSI B71.4 safety certification.

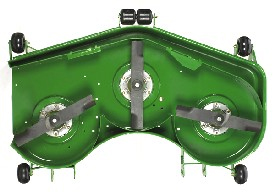

72-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck

72-in. 7-Iron Pro Side-Discharge Mower Deck

72-in. 7-Iron Pro Side-Discharge Mower Deck

Features include:

- Blade tip speed of 18,000 fpm (5486 m/min) for more blade strikes per inch mowed.

- Trim-edge bumper reduces damage to the mower deck and property.

- Redesigned front baffle manages airflow and controls clippings better.

- Spindle pocket reinforcement gives even greater structural durability.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Adjustable anti-scalp wheels help smooth out the mowing job.

- Standard semi-pneumatic caster tires will not go flat from punctures.

The mower is designed to provide exceptional cut quality at higher travel speeds:

- The mower deck is stamped from 7-gague, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside, with fewer sharp corners, for reduced material buildup.

- Provides precision components and long deck life

- Single piece of steel means no welds to break

- Provides a smooth underside, without corners, reducing material buildup

- 0.75-in. (1.9-cm) solid steel bar is welded to mower deck perimeter for added strength.

- The rounded corners of the stamped deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- A deep-deck design of 5.5-in. (14-cm) delivers excellent airflow so material can be processed quickly and efficiently.

- 1-in. to 6-in. (2.5-cm to 12.7-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

Unique baffling system allows grass to stand up before being cut, producing a uniform length and appearance:

- Baffling system eliminates clumping, blowout, and windrowing.

- Wide discharge opening provides even clipping dispersal for an excellent, finished appearance in all conditions.

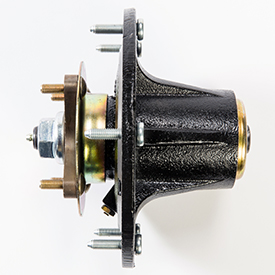

Heavy-duty blade spindles

Cast-iron spindle housing

Cast-iron spindle housing

Cast-iron spindle housing

Cast-iron spindle housing

The mower spindle housings are made of ductile cast iron.

Key benefits of ductile cast-iron spindle housings:

- Ductile cast-iron material provides superior impact strength.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Grease fitting is mounted at the top for easy access.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- The 8-in. (20.3-cm) diameter housing distributes loads and impacts to minimize deck-shell damage.

- Spindle allows ability to be rebuilt.

NOTE: The 72-in. (183-cm) 7-Iron V-Flex Side-Discharge Mower Deck has an aluminum center spindle housing. The outside blades are driven by cast-iron gearboxes.

60-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

Features include:

- Blade tip speed of 18,000 fpm (5486 m/min) for more blade strikes per inch mowed.

- Trim-edge bumper reduces damage to the mower deck and property.

- Redesigned front baffle manages airflow and controls clippings better.

- Blade spindle housings are made of ductile cast iron

- Gusseted design puts reinforcement where it is needed.

- Spindle pocket reinforcement gives even greater structural durability.

- Adjustable anti-scalp wheels help smooth out the mowing job.

- Standard semi-pneumatic caster tires will not go flat from punctures.

The mower is designed to provide exceptional cut quality at higher travel speeds:

- The mower deck is stamped from 7-gauge, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside, with fewer sharp corners, for reduced material buildup.

- Provides precision components and long deck life

- Single piece of steel means no welds to break

- Provides a smooth underside, without corners, reducing material buildup

- 0.75-in. (1.9-cm) solid steel bar is welded to mower deck perimeter for added strength.

- The rounded corners of the stamped deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- A deep-deck design of 5.5-in. (14-cm) delivers excellent airflow so material can be processed quickly and efficiently.

- 1-in. to 6-in. (2.5-cm to 12.7-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

Unique baffling system allows grass to stand up before being cut, producing a uniform length and appearance:

- Baffling system eliminates clumping, blowout, and windrowing.

- Wide discharge opening provides even clipping dispersal for an excellent, finished appearance in all conditions.

62-in. (157-cm) FastBack Mower Deck

62-in. FastBack Mower Deck

62-in. FastBack Mower Deck

The 62-in. (157-cm) FastBack rear-discharge mower is ideally suited for:

- Areas where people are present

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Conditions and applications:

- Areas with long grass and weeds

- Areas where customer is not as concerned about having a wide dispersal of grass (park areas, roadsides, etc.)

- Government bids that specify a rear discharge mower.

Key features of the 62-in. (157-cm) Rear-Discharge Mower Deck include:

- Mower deck is constructed of 7-gauge, 0.179-in. (4.6-mm) steel for the strength to stand up to the demanding use of commercial and municipal mowing applications.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Deck is constructed with a unique baffling system that reduces clumping and windrowing and produces a finished appearance that competitive rear-discharge mowers cannot match.

- The belt-drive system has an easy-to-adjust tension device.

- By using a spring system, the risk for over tensioning is eliminated, ensuring a long belt life and excellent performance during the season.

- For easy service and maintenance, the deck can be rotated into the vertical locked service position.

- Deep-deck design increases airflow so more material can be processed.

- Operator can trim with either side.

- Dual side trimming increases operator productivity.

- 1-in. to 6-in. (2.5-cm to 15.2-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

-

Gauge wheels, rollers, or side-mounted skid shoes lift the deck over uneven surfaces for a well-groomed appearance.

-

Double-captured anti-scalp wheels provide increased durability.

-

Easy lift and lock system for service purposes.

-

Standard semi-pneumatic caster tires will not go flat when punctured.

-

Spindles can be greased without removing belt shields.

-

1-in. (2.5-cm) cold-forged spindles are strong for long life.

-

Heat-treated to provide additional strength

-

-

Certified to European (CE) standards

72-in. (183-cm) FastBack PRO Mower Deck

72-in. FastBack PRO Mower Deck

72-in. FastBack PRO Mower Deck

The 72-in. (183-cm) Rear-Discharge FastBack PRO Mower Deck is ideally for professional landscapers and government municipalities requiring rear discharge placement of grass and debris, John Deere FastBack PRO rear-discharge mower decks deliver a commercial mowing solution. Advantages of a rear-discharge mower include:

- Less chance of damage from objects being thrown from the mower deck

- Time savings with the ability to mow closely around fixed objects with either side of the deck

- A cleaner mowing experience by lessening the amount of debris that can blow onto the operator

A rear-discharge mower deck is ideally suited for:

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Areas with long, grassy spots that need to be cut, where you are not as concerned about wide dispersal of grass (park areas, roadsides, etc.)

- Some government bids specify that the mower is equipped with a rear discharge.

Key features of the 72-in. (183-cm) Rear-Discharge Mower Deck include:

- Mower deck is constructed of 7-gauge, 0.179-in. (4.6-mm) steel for the strength to stand up to the demanding use of commercial and municipal mowing applications.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Deck is constructed with a unique baffling system that reduces clumping and windrowing and produces a finished appearance that competitive rear-discharge mowers cannot match.

- Operator can trim with either side.

- Dual side trimming increases operator productivity.

- Trim-edge bumpers on each side reduces damage to the mower deck and property.

- The belt-drive system has an easy-to-adjust tension device.

- By using a spring system, the risk for over tensioning is eliminated, ensuring a long belt life and excellent performance during the season.

- For easy service and maintenance, the deck can be rotated into the vertical locked service position. Deep-deck design increases airflow so more material can be processed.

- 1-in. to 6-in. (2.5-cm to 15.2-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

- Gauge wheels or rollers lift the deck over uneven surfaces for a well-groomed appearance.

- Double-captured anti-scalp wheels provide increased durability. Easy lift and lock system for service purposes.

- Standard semi-pneumatic caster tires will not go flat when punctured. Spindles can be greased without removing belt shields.

- 1-in. (2.5-cm) cold-forged spindles are strong for long life.

- Heat-treated to provide additional strength

- Certified to European (CE) standards

Mower deck specifications

|

60-in. (152-cm) 7- Iron PRO Side- Discharge |

62-in. (157-cm) FastBack Rear- Discharge |

72-in. (183-cm) 7- Iron PRO Side- Discharge |

72-in. (183-cm) FastBack PRO Rear- Discharge |

Gauge (thickness) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

Cutting height |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

Caster wheel type |

Semi-pneumatic |

Semi-pneumatic |

Semi-pneumatic |

Semi-pneumatic |

Gauge wheels |

Yes, front and rear |

Yes, front and rear |

Yes, front and rear |

Yes, front and rear |

Deck oscillation relative to ground plane |

+/- 15 degrees |

+/- 15 degrees |

+/- 15 degrees |

+/- 15 degrees |

Lateral deck tilt |

+/- 8 degrees |

+/- 8 degrees |

+/- 8 degrees |

+/- 8 degrees |

Deck installed at factory |

No |

No |

No |

No |

Time required for one person to install or remove deck (without tools) |

10 minutes |

10 minutes |

10 minutes |

10 minutes |

Time to change height of cut |

3 minutes without tools |

3 minutes without tools |

3 minutes without tools |

3 minutes without tools |

Belt type |

Kevlar belt |

Kevlar belt |

Kevlar belt |

Kevlar belt |

Belt shield type |

Plastic |

Plastic |

Plastic |

Plastic |

Belt shield time to remove or install |

2 minutes or less |

2 minutes or less |

2 minutes or less |

2 minutes or less |

Blade type |

High lift |

Medium lift |

High lift |

Medium lift |

Blade tip speed |

18,000 fpm (5,486 m/min) |

16,000 fpm (4,877 m/min) |

18,000 fpm (5,486 m/min) |

18,000 fpm ( 5,486 m/min) |

Spindles |

3 |

3 |

3 |

3 |

Spindle-housing material |

Ductile cast iron |

Ductile cast iron |

Ductile cast iron |

Ductile cast iron |

Deck level laterally when raised |

Yes |

Yes |

Yes |

Yes |

Discharge |

Side |

Rear |

Side |

Rear |

Mowing width |

60 in. (152 cm) |

62 in. (157 cm) |

72 in. (183 cm) |

72 in. (183 cm) |

Overall width (chute down) |

74 in. (188 cm) |

64 in. (163 cm) |

86 in. (218 cm) |

74 in. (188 cm) |

Weight |

--- |

--- |

--- |

--- |

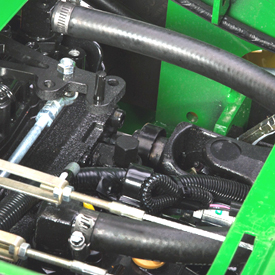

PTO shaft drive is easy to access for quick-change of equipment

Front mower PTO shaft drive

Front mower PTO shaft drive

Live, independent power take-off (PTO) powers a mower deck, rotary broom, or two-stage snow blower:

- PTO can be engaged or disengaged on the go for greater productivity.

- Hydraulic PTO clutch has delay relief valve for soft engagement.

- Wet clutch design provides long life.

- PTO is easily accessible.

Tires are matched to the machine size and mower widths

1550, 1570, 1575 tires

Tires

Tires

Standard drive tires:

- 23x10.5-12 or 23x8.5-12 (1550, 1570)

- 23x10.5-12 (1575)

Available steering tires: 18x8.5-10 (4WD) or 18x8.5-8 (2WD)

1580, 1585 tires

Standard drive tires: 26x12-12, 6 PR drive tires (1580, 1585)

Standard steering tires: 20x10.00-10, 6 PR steering tires (1580, 1585)

Optional mulching kits add versatility to the mower decks

Typical mulch kit shown

Typical mulch kit shown

Kits are available to convert the 60-in. (152-cm) and 72-in. (183-cm) 7-Iron™ PRO Side-Discharge Mower Decks into mulching decks for use in grass and leaves.

The mulch kits include mulching blades, baffles, end covers, and attaching hardware.

Standard premium ComfortCab provides superior comfort and performance

1585 TerrainCut™ Front Mower and rotary broom

1585 TerrainCut™ Front Mower and rotary broom

The ComfortCab is standard equipment on the 1575 and 1585 TerrainCut™ Front Mowers. It is one of the most comfortable and easy-to-use cabs available anywhere. This premium cab was developed using extensive research and testing, and some of the most advanced design techniques available.

Cab vehicles are designed for operators who demand superior comfort and performance:

- Large-property owners

- Commercial operators

- Governmental agencies

- Producers

Whether mowing or doing other implement work (such as use of the snow blower, rotary broom, or front blade), the TerrainCut Front Mowers have the versatility and muscle to get the job done, all while protecting the operator from the elements.

Design

Standard equipment ComfortCab

Standard equipment ComfortCab

ComfortCab visibility from operator's seat

ComfortCab visibility from operator's seat

Operators are sure to appreciate what this cab has to offer, beginning with a design that has visibility in mind. The cab is designed with robust mounting points integrated into the rollover protective structure (ROPS).

The spacious design and carefully laid-out interior provide a full 360 degrees of visibility:

- Operators enjoy an unobstructed view no matter what task is being performed.

- Operator fatigue caused by awkward bending is reduced, leading to increased overall productivity.

- The ample headroom and curved glass on all four sides provide a roomy interior and give operators a big-cab feel.

Climate control system

Cab air filter

Cab air filter

ComfortCab high-quality interior

ComfortCab high-quality interior

Operators are well-protected from the elements with a high-performance climate-control system providing heating and air conditioning:

- The climate-controlled cab makes any task more enjoyable, whether on a frigid winter day or a hot summer day.

- A standard high-efficiency clean-air filter reduces dust and allergen particles.

Heater and air-conditioning controls and vents

Heater and air-conditioning controls and vents

Heat and air-conditioning roof vents

Heat and air-conditioning roof vents

A high-quality climate-control system for maximum operator comfort is standard equipment with the ComfortCab on the 1575 and the 1585:

- Heater and air-conditioner controls are conveniently located in headliner.

- Vents in the roof are located on both sides of the operator.

ComfortCab includes rollover protection for the operator

1585 TerrainCut Front Mower

1585 TerrainCut Front Mower

The ComfortCab includes ROPS protection for the operator. A retractable seat belt is included as standard equipment.

SiriusXM is a trademark of Sirius XM Radio Inc. iPod is a trademark of Apple Inc.

ComfortCab features

Superior operator comfort and visibility

Superior operator comfort and visibility

Right-hand controls, instruments, and cup holder

Right-hand controls, instruments, and cup holder

Several features are integrated into the design of the cab that deliver superior operator comfort and visibility. These features include:

- Ultra-quiet interior with noise dampening foam floor mats

- Curved glass for 360-degree visibility and spacious interior

- Raised header bar for maximum front visibility

- Right-hand control center with the most frequently used controls at the operator's fingertips

- Tilt steering

- Removable floor

- In-base equipment, deluxe cloth seat with a retractable seat belt

- Standard armrests for additional operator comfort

- Inside rearview mirror for rear visibility

- Interior dome light for illumination in low-light conditions

- Standard sun visor to block unwanted sunlight

- Creature comforts like:

- Convenient cup holder

- 12-V power supply

- Integrated handle providing support for ingress and egress

- Lockable, push-button entry handles

- Left-side step for convenient ingress and egress (1585 only)

Optional comfort features include:

- Optional dual exterior rearview mirrors for added rear visibility

- Optional radio mount kit and a choice of field-installed stereos are available:

- Stereo with AM/FM, weatherband, SiriusXM® Satellite, and iPod® ready

- John Deere/Delco AM/FM stereo with single compact disc player, clock, front audio input jack for MP3 players, and weatherband

- Stereo with AM/FM, weatherband, SiriusXM Satellite, and iPod ready

Standard and optional cab operating features

Standard two-speed windshield wiper control

Standard two-speed windshield wiper control

Optional radio

Optional radio

The cab has been designed with many standard features that provide ease and convenience for the operator:

- Standard two-speed front windshield wiper with windshield washer to keep the front glass clear

- Dual roof-mounted forward LED work lights for optimum forward visibility at night

- Integrated warning lights/turn signals, protected from trees and branches

- Double-spool auxiliary hydraulic valve with forward-mounted couplers (1575 and 1585)

The cab has been designed to easily accept accessories that improve operator comfort and performance:

- Pre-wired for optional accessories like a radio, rear work lights, and beacon light

- Dual roof-mounted rearward work lights for optimum rearward visibility at night

Seat

Seat and controls

Seat and controls

Comfortable cloth seat

Comfortable cloth seat

A comfortable cloth seat is provided for the operator.

A deluxe cloth air-ride seat with retractable seat belt is in base equipment on cab models:

-

An ergonomically sculpted seat cushion, lumbar, adjustable seat back, air suspension, and seat armrests are combined to provide excellent operator comfort and support.

-

The operator can adjust suspension by increasing/decreasing pressure to place arrow in center of gauge for optimum comfort.

-

Using a lever located under the seat, the seat is adjustable fore and aft for operator height.

-

Retractable seat belts prevent belts from becoming tangled in the seat suspension and controls.

Standard lighting

Two standard front LED lights

Two standard front LED lights

Optional lighting includes:

-

Dual roof-mounted adjustable rear work lights

-

Beacon light

Cab safety features

-

ROPS - Certified to the highest industry standards for maximum operator protection

-

Operator presence system

- Right-side emergency exit

-

Tempered safety glass in case of breakage

-

Roof-mounted warning lights/turn signals for road transport — two front and two rear

Easy-to-operate controls maximize productivity

1585 TerrainCut™ Front Mower with ComfortCab

1585 TerrainCut™ Front Mower with ComfortCab

1585 TerrainCut Front Mower and rotary broom

1585 TerrainCut Front Mower and rotary broom

Hydrostatic power steering provides the following benefits:

- Makes it easy to turn the unit, for less operator fatigue

- Allows quick turns – two turns lock to lock – for excellent productivity

The steering console offers the following:

- Throttle

- Key switch

- Headlight switch

- T4 display

Operator controls (1570 shown)

Operator controls (1570 shown)

Controls conveniently located

Controls conveniently located

Heads-up indicator lights are always visible to the operator for easy monitoring.

Console information/warning lights include the following:

- Hour meter

- Engine oil pressure

- Engine coolant temperature

- Hydraulic oil over temperature light and alarm PTO shutdown

- Air preheater

- Power take-off (PTO) operation indication

Maneuverability:

- Turn radius of 13 in. (33 cm)

- Uncut circle of 28 in. (71.1 cm) with a 72-in. (183-cm) 7-Iron™ PRO mower deck

- Deck offset and pulled rearward

- Tail-follows-the-trail trimming capability with 72-in. (183-cm) side-discharge mower deck

- Steered wheels (tail) stay within the path (trail) cut by the mower deck, allowing maneuverability without the rear of the machine contacting mowing obstacles

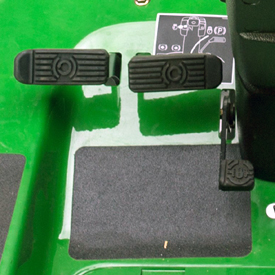

Master stop brake/directional foot pedals

Master stop brake/directional foot pedals

Two-pedal foot control:

- Allows operator to select speed and direction with just the touch of a toe

- Keeps both hands free for steering and operating controls

Master stop brake (parking brake):

- Provides stopping power to both drive wheels

- Disengages the power take-off (PTO)

- Disengages the optional cruise control

- Used also for a parking brake

Individual turn-assist brakes and differential lock

Individual turn-assist brakes and differential lock

Individual turn-assist brakes:

- Provides additional traction when operating on hillsides

- Ideal for tight trimming situations

- Work in conjunction with hydrostatic foot controls to stop or slow the unit for turns

Differential lock:

- Locks both front drive wheels together for added traction

- Easily engaged with the left foot

Four-wheel drive (4WD) lever (1570 shown)

Four-wheel drive (4WD) lever (1570 shown)

Control levers

Control levers

A two-speed transaxle shift lever is standard on the 1580 and 1585.

The 4WD control lever is standard on the 1575, 1580, and 1585; it is a factory-installed option on the 1550 and 1570.

Safety starting system helps protect the operator and others

1570 TerrainCut Front Mower mowing grass

1570 TerrainCut Front Mower mowing grass

TerrainCut™ Front Mowers have an operator-presence system.

To start the engine the following conditions must be met:

- Master brake must be depressed or the parking brake locked; the hydrostatic foot controls will then be in the neutral position.

- PTO must be disengaged

- Ignition key must be used.

In addition, once the engine is running, an interlock automatically shuts the engine and PTO off if the operator leaves the seat. To keep the engine running, the operator must disengage the PTO and set the parking brake before dismounting.

Tilt steering is standard equipment

Tilt steering is standard equipment

Tilt steering is standard equipment

The three-piece steering column provides the following:

- Easy access to the steering valve and electrical components

- Better fit-up and appearance

- Easy adjustment to accommodate all operators

Tilt steering

Tilt steering column

Tilt steering column

Tilt steering column allows the operator to adjust to the most comfortable position:

- Allows additional clearance for platform entry and exit

- Over 15 in. (38.1 cm) of travel

- Works in conjunction with the seat to accommodate all operators, regardless of size

Brakes and differential lock are convenient to use for maximum productivity

Wet-disk brakes/differential lock

Wet-disk brakes/differential lock

Wet-disk brakes are standard equipment:

- Provide positive stopping power and long life

- Require minimal adjustment

- Individual turn brakes are located on left side of platform

The differential lock is also included as standard equipment:

- Locks both front drive wheels together for extra traction, when needed

- Conveniently located pedal to allow the operator to engage the differential lock with the left foot while maintaining speed and direction (forward or reverse) with the right foot

12-V power outlet is convenient to use

12-V power outlet

12-V power outlet

The 12-V power outlet can be used to recharge radios and cell phones, popular tools used by commercial cutters.

The outlet is conveniently located under the front of the seat.

Certification ensures compliance with safety standards

Rollover protective structure (ROPS)

Rollover protective structure (ROPS)

TerrainCut Front Mowers comply with ANSI B71.4 2004 safety certification specification.

The ROPS complies with the U.S. Occupational Safety and Health Administration (OSHA) 1928.51 standard for rollover protection.

Manage your commercial mowing fleet using John Deere Operations Center™

TerrainCut™ Front and Wide-Area Mowers

TerrainCut™ Front and Wide-Area Mowers

Overview

A JDLink™ M Modem - 4G connects a commercial mower to the John Deere Operations Center, which enables you to manage your fleet more efficiently, increase productivity, and reduce labor costs. With a modem and Operations Center, you are always connected to the work in progress and can make timely adjustments to keep your fleet mowing.

JDLink M Modem - 4G

JDLink M Modem - 4G

JDLink M Modem - 4G

A JDLink M Modem - 4G is standard equipment on model year 2024 and newer TerrainCut Front and Wide-Area Mowers. A modem can be field installed on:

- Model year 2024 and newer Z700 ZTrak™ Mowers

- Most model year 2024 and newer Z900 ZTrak Mowers

- Model year 2024 and newer Q800 QuikTrak™ Mowers

- Model year 2022-2023 TerrainCut Front Mowers

- Model year 2023 TerrainCut Wide-Area Mowers

See compatibility section for serial number breaks and requirements.

John Deere Operations Center

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

The John Deere Operations Center tracks your fleet and provides tools to analyze mower data. The connected features vary by mower model.

Models |

Location and status |

GPS speed |

Geofencing and curfews |

Engine hours |

Maintenance planner |

Machine Analyzer Tool |

Fuel level and consumption |

Diagnostic trouble codes |

Service Advisor Remote |

Z700 ZTrak Mowers |

X |

X |

X |

Key |

X |

--- |

--- |

--- |

--- |

Gasoline-powered Z900 ZTrak Mowers |

X |

X |

X |

Key |

X |

--- |

--- |

--- |

--- |

Z994R ZTrak Mowers |

X |

X |

X |

Key |

X |

--- |

--- |

--- |

--- |

E Series QuikTrak Mowers |

X |

X |

X |

Key |

X |

--- |

--- |

--- |

--- |

Q820M, Q850M, and Q850R QuikTrak Mowers |

X |

X |

X |

Sync |

X |

X |

X |

X |

--- |

Q865R EFI QuikTrak Mowers |

X |

X |

X |

Sync |

X |

X |

X |

X |

X |

1550 TerrainCut Front Mowers |

X |

X |

X |

Key |

X |

--- |

--- |

--- |

--- |

1570, 1575, 1580, and 1585 TerrainCut Front Mowers |

X |

X |

X |

Sync |

X |

X |

--- |

X |

X |

1600 TerrainCut Wide-Area Mowers |

X |

X |

X |

Sync |

X |

X |

--- |

X |

X |

Location and status

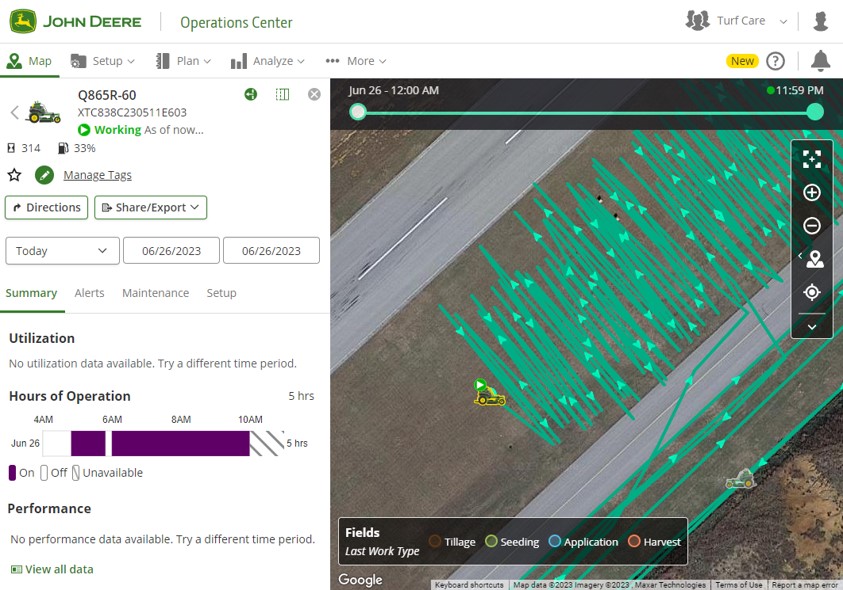

Operations Center map displaying past locations of a mower

Operations Center map displaying past locations of a mower

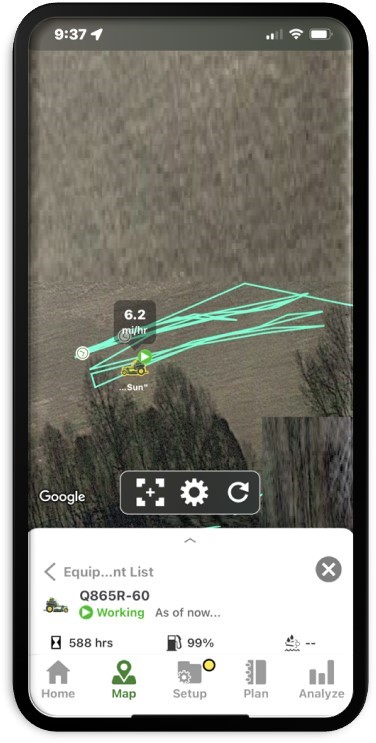

Mobile view of Operations Center map showing GPS speed

Mobile view of Operations Center map showing GPS speed

The JDLink M Modem - 4G regularly transmits the location and operational status of each mower in the fleet so you can monitor mowing progress on the Operations Center.

- Location history-Display of map with current and past locations of each mower.

- GPS Speed-Maps each mower’s current and past speeds, based on GPS location data, so you can target operator training. GPS speed is only viewable on Apple iOS and Android mobile apps.

- Geofencing-Alerts when a mower enters or exits a prescribed area, for example if the mower has been stolen or an operator entered an area that should not be mowed.

- Curfews-Alerts if the mower is operating outside prescribed times, for example residential areas with early-morning noise restrictions.

Engine hours

The modem regularly transmits the mower’s engine hours to inform maintenance planning and balance use.

- Sync-The mower reports actual engine hours to the Operations Center.

- Key-Engine hours are estimated by monitoring the key switch. Engine hours can be corrected in Operations Center.

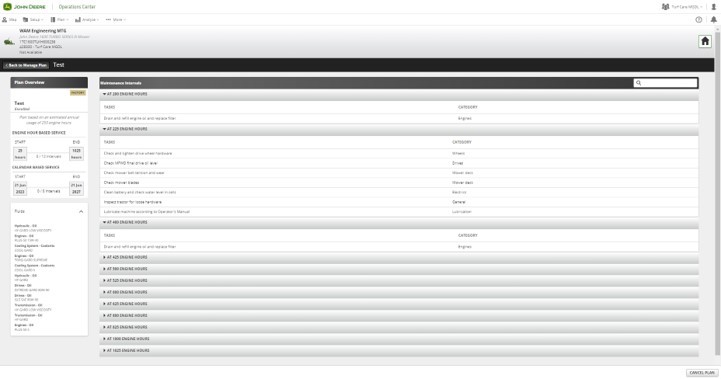

Maintenance planner

Operations Center Maintenance Planner

Operations Center Maintenance Planner

Factory or custom maintenance plans can be established in Operations Center. Maintenance alerts are sent when engine hours reach maintenance intervals.

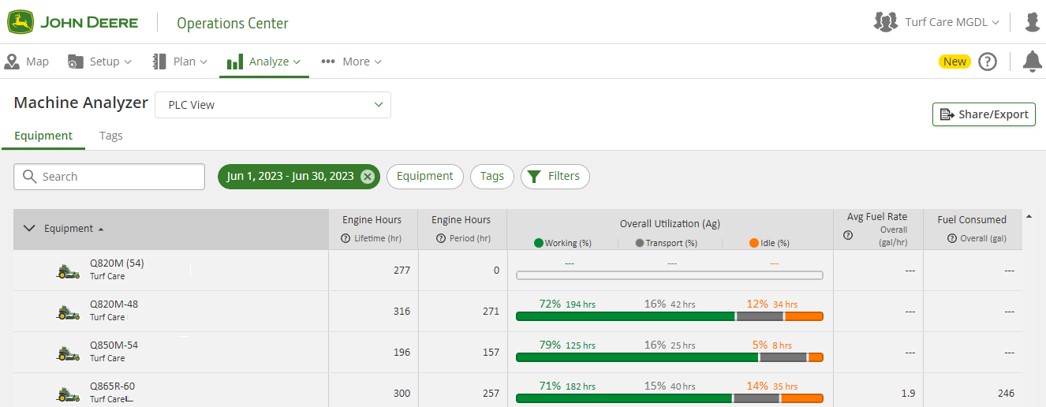

Machine Analyzer Tool

Operations Center Machine Analyzer Tool

Operations Center Machine Analyzer Tool

On select products, the modem reports the time the mower spent transporting, idling, and working. The Operations Center’s Machine Analyzer tool reports usage data which allows you to analyze operator behavior, identify causes of low productivity, and initiate corrective actions.

Fuel level

On select products, the modem reports the fuel level. On these products, an analysis of fuel consumption is available in the Operations Center Machine Analyzer Tool. Measuring fuel consumption enables you to address causes of excessive fuel use.

Diagnostic trouble codes (DTCs)

On select products, the modem transmits the trouble codes generated by the mower’s control units to the Operations Center. Addressing DTCs can reduce downtime and repair costs. For example, a low-engine oil pressure DTC can indicate an engine is low on oil. Addressing the issue can prevent costly downtime and repairs.

Service Advisor Remote

On select products, John Deere dealers can perform remote diagnostics, software programming, and adjustments without the cost of a service call.

Compatibility

A JDLink M Modem - 4G is standard equipment on model year 2024 and newer (SN 110,001-) TerrainCut Front Mowers and model year 2024 and newer (SN 690,001-) TerrainCut Wide-Area Mowers.

A JDLink M Modem - 4G can be field installed on the commercial mowing products listed below. Field installation attachments simplify modem installation, and include brackets, mounting hardware, harness, and instructions. Field installation requires a JDLink M Modem - 4G to be ordered separately.

Model |

Compatible model years |

Installation attachment |

Z700 ZTrak Mowers |

2024 and newer (SN 080,001-) |

BUC11759* |

Gasoline-powered Z900 ZTrak Mowers |

2024 and newer (SN 130,001-) |

BUC11759* |

Z994R ZTrak Mowers |

2024 and newer (SN 070,001-) |

BUC11759* |

Z997R ZTrak Mowers |

2021 and newer (SN 800,001-) |

To be determined |

QuikTrak Mowers |

2024 and newer (SN 010,001-) |

BUC11744* |

R Series commercial walk-behind mowers |

To be determined |

To be determined |

TerrainCut Front Mowers |

2022-2023 (SN 080,001-110,000) |

BUC11797* |

1600 TerrainCut Wide-Area Mowers |

2023 (SN 680,001-690,000) |

BUC11797* |

*Expected by early 2024

Serviceability is designed-in to reduce maintenance cost and increase uptime

Engine hood

Large screened area of engine hood

Large screened area of engine hood

Hood latch

Hood latch

Engine hood includes large screened area:

- Minimizes the amount of material that can get to the cooling radiators

- Minimizes the need to clean the hood screens

Hood latch keeps the hood securely in place, providing an optimum seal:

- A single hood latch is located on top of the hood behind the seat.

Engine hood opens to the rear

Engine hood opens to the rear

Designed-in service accessibility

Designed-in service accessibility

Designed-in service accessibility helps ensure daily maintenance is completed to keep the machine operating at peak performance.

The hood opens rearward, exposing the following:

- Engine

- Oil and fuel filter

- Hydraulic oil cooler

- Radiator check/fill

The hood can be totally removed, if necessary. The seat flips forward for access to air filter, fuse bank, engine oil dipstick, and front of engine.

Condenser release knob

Condenser release knob

Condenser tilted back to permit cleaning

Condenser tilted back to permit cleaning

Easy-to-turn knobs are provided to release the air conditioning condenser (1575 and 1585 only) and fuel and hydraulic oil coolers so they can be tilted back to permit thorough cleaning between them and the engine coolant radiator.

Quick response (QR) codes link to owner information web pages

QR code label on control console

QR code label on control console

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on the control console near the seat. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

Foot platform access panel

Removable foot platform

Removable foot platform

The panel on the foot platform can be removed for access to the transaxle, PTO shaft, and most linkages.

Easy-to-read daily service decal is located on the bottom of the foot platform panel:

- Provides access to easily hook up driveshaft when changing implements

- Makes it more likely service will be performed at the optimum time, thus ensuring the highest level of performance and uptime

Panel on foot platform removed

Panel on foot platform removed

Removal of the foot platform gives convenient access to the driveshaft that powers the mower deck, snow blower and rotary broom:

- Helps make changing from one front implement to another easier and more convenient

Hydraulic hoses have reusable O-ring seal (ORS) fittings:

- ORS fittings seal at a lower torque to prevent leaks.

- Fittings can be removed from a damaged hose and installed on another hose.

- Downtime and cost for repairs are reduced considerably.

Rotate For Service™ (RFS) feature shown

Rotate For Service™ (RFS) feature shown

RFS service lockout latch

RFS service lockout latch

RFS feature provides access for cleaning and maintenance of the mower decks:

- The service-latch pin allows mower deck to lock into position to ensure deck is held in position for cleaning or service.

- The top-greaseable spindle grease fittings can be accessed without removing the belt covers.

Trailering features are included to reduce the time and cost to move equipment

Trailering features are designed-in for convenience:

- Designed-in trailer tie-downs are located at the front and rear of the machine.

- 26-degree deck lift will clear the steepest trailer ramps for easy loading and unloading.

- Rotate For Service™ (RFS) decks take up less room when transporting on trailers, allowing more room for other important equipment.

Remote battery posts

Remote battery posts

Remote battery posts

Remote battery posts simplify jump starting. Both positive and negative posts are located in front of the right rear steer tire.

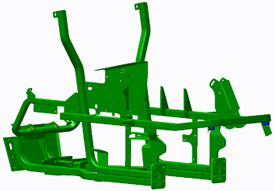

Welded frame structure is made of high-strength steel

High-strength, tubular steel frame

High-strength, tubular steel frame

The revolutionary tubular, high-strength welded steel frame provides durability and allows major components to be located lower in the machine:

-

The design results in a lower center of gravity for better stability and traction on hillsides and slopes.

-

Rollover protective structures (ROPS) are integral members of the frame.

Durable design

Durability features of the frame include:

- Heat-treated cast-iron axles with 1.24-in. (3.15-cm) kingpins

- Internal wet-disk brakes

- Hydraulic PTO clutch, with brake

- Provides smooth engagement and long life

- Hydrostatic oil cooler

- O-ring seal (ORS) hydraulic fittings

- Integrated, shaft-driven power take-off (PTO)

- Sealed relays and electrical connectors

- Heavy-duty, dual hydraulic cylinders

- Nodular cast-iron lift arm sockets

- Cast-iron rear bumper

Hydrostatic transmission and transaxle are heavy-duty to maximize uptime

Kanzaki 30-cc transmission

Kanzaki 30-cc transmission

A Kanzaki® 30-cc transmission is used for reliable operation.

Durability features include the following:

- High-capacity hydrostatic transmission and heavy-duty transaxle maximize performance and uptime and minimize cost of maintenance.

- Charge pump is used to efficiently deliver oil to the transmission.

- Oil cooler helps maintain optimum transmission oil temperature for superior performance and longer transmission life in the most challenging operating conditions.

- Maximum forward top speed is 12 mph (19.3 km/h) on the 1550, 1570, and 1575 and 15 mph (24.1 km/h) on the 1580 and 1585.

- Self-bleeding design helps keep air out of the system.

Kanzaki is a trademark of Kanzaki Kokyukoki Manufacturing Company.

Two-function mechanical rear-wheel drive for optimum use of the four-wheel drive feature

Mechanical rear-wheel drive axle

Mechanical rear-wheel drive axle

Mechanical rear-wheel drive is available as standard equipment (1575, 1580, 1585) or as a factory-installed option (1550, 1570):

- On-demand four-wheel drive automatically engages and disengages as needed.

- Constantly maximizes trimming ability

- Offers better fuel economy than full-time four-wheel drive

- Provides better steering tire wear than full-time four-wheel drive

- Increases traction and trimming ability to allow a novice operator to mow like an expert

- Works in the forward direction only

- Full-time four-wheel drive is on at all times.

- Can be engaged or disengaged on the go

- Provides maximum traction and flotation in poor conditions

- Works in reverse as well as the forward direction

- Two-wheel drive position is available on 1580 and 1585 with two-speed transaxle.

- Disengages rear axle when transporting at high ground speeds

Tail-follows-the-trail design helps avoid obstacles in turns

Tail follows the trail

1585 TerrainCut™ Front Mower

1585 TerrainCut™ Front Mower

Tail-follows-the-trail trimming with 72-in. (183-cm) mower decks. Steered wheels (tail) stay within the path (trail) cut by the mower deck, allowing maneuverability without the rear of the machine contacting mowing obstacles.

Maneuverability:

- Turn radius 13 in. (33 cm)

- Uncut circle – 28 in. (71cm) with a 72-in. (183-cm) 7-Iron PRO mower deck

- Deck offset for increased trim capability

Front mower ballast requirements

Front mowers must be properly ballasted for both good performance and safe operation. Ballast requirements differ depending on the front mower model and the implement being used.

The chart below gives the minimum ballast requirements for the various product configurations. Additional ballast is recommended for operating on slopes or other conditions that may warrant it.

NOTE: Use only implements and accessories recommended by the manufacturer.

Front mowers and current (model year 2015 and later) implements

TerrainCut™ 1500 Series Front Mowers |

|||||||||

Product Configuration |

60-in. (152- cm) Side- Discharge Deck (7- Iron™ PRO) |

72-in. (183- cm) Side- Discharge Deck (7- Iron PRO) |

62-in. (157- cm) Rear- Discharge Mower Deck |

72-in. (183- cm) Rear- Discharge Mower Deck |

60-in. (152- cm) HD Front Blade |

47-in. (119- cm) HD Two-Stage Snow Blower |

60-in. (152- cm) HD Two-Stage Snow Blower |

60-in. (152- cm) Rotary Broom |

43-in. (109- cm) Drop Spreader (Order Zone) |

1550 Front Mower 2WD |

1* |

2* |

1* |

2* |

0 |

2* |

3* |

1* |

NA*** |

1550 Front Mower 4WD |

0 |

1* |

0 |

1* |

0 |

2* |

2* |

0 |

Wide track |

1570 Front Mower 2WD |

1* |

2* |

1* |

2* |

0 |

2* |

3* |

1* |

NA*** |

1570 Front Mower 4WD |

0 |

1* |

0 |

1* |

0 |

2* |

2* |

0 |

Wide track |

1575 Front Mower |

Narrow track + 4 * |

Wide track + 5* |

Narrow track + 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

1* |

NA*** |

6* |

Wide track + 1 wheel weight on each side** + 3 weights* |

With 60-in. Rotary Broom: wide track + 2 wheel weight on each side** or with 60-in. Snow Blower: wide track |

1580 Front Mower |

0 |

1* |

0 |

1* |

0 |

NA*** |

2* |

0 |

Wide track |

1585 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track + 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

1* |

NA*** |

6* |

Wide track + 1 wheel weight on each side** + 3 weights* |

With 60-in. Rotary Broom: wide track + 2 wheel weight on each side** or with 60-in. Snow Blower: wide track |

1400 and 1500 Series II Front Mowers |

|||||||||

1420 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1435 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1445 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1545 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

NA*** |

6* |

6* |

NA*** |

1565 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

NA*** |

6* |

6* |

NA*** |

1575/1585 Cab models: Rim design allows for tire assembly to be mounted in two different configurations, a narrow track or wide track width to meet ballast requirements. |

|||||||||

*42-lb (19-kg) (UC13263) Quik-Tatch weight (installation requires TCB10303, rear weight mounting kit). |

|||||||||

**50-lb (23-kg) front wheel weight(s) required (installation requires BM18101, mounting hardware kit). |

|||||||||

***NA - Not recommended for use on front mower. |

|||||||||

NOTE: Ballast requirements may change. Always refer to the implement owner's manual for the appropriate ballast requirements. |

|||||||||

Front mowers and model year 2014 and prior implements

1400 and 1500 Series II Front Mowers |

|||||||||||

Product Configuration |

60-in. (152- cm) Side- Discharge Deck (7- Iron™ and 7-Iron II) |

72-in. (183- cm) Side- Discharge Deck (7- Iron and 7- Iron II) |

62-in. (157- cm) Rear- Discharge Mower Deck |

72-in. (183- cm) Rear- Discharge Mower Deck |

MCS 600 Hydraulic Dump |

Soft cab |

Hard cab |

60-in. (152-cm) HD Front Blade |

47-in. (119-cm) HD Two- Stage Snow Blower |

60-in. (152-cm) HD Two- Stage Snow Blower |

60-in. (152- cm) Rotary Broom |

1420 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1435 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1445 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1545 Series II Front Mower |

NA |

1* |

NA |

1* |

0 |

0 |

0 |

6* |

NA |

6* |

6* |

1565 Series II Front Mower |

NA |

1* |

NA |

1* |

0 |

0 |

0 |

6* |

NA |

6* |

6* |

1500 TerrainCut Front Mowers |

|||||||||||

1550 Front Mower 2WD |

1* |

2* |

1* |

2* |

NA |

NA |

NA |

0 |

2* |

3* |

1* |

1550 Front Mower 4WD |

0 |

1* |

0 |

1* |

NA |

NA |

NA |

0 |

2* |

2* |

0 |

1570 Front Mower 2WD |

1* |

2* |

1* |

2* |

NA |

NA |

NA |

0 |

2* |

3* |

1* |

1570 Front Mower 4WD |

0 |

1* |

0 |

1* |

NA |

NA |

NA |

0 |

2* |

2* |

0 |

1575 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

NA |

NA |

NA |

1* |

NA |

6* |

Wide track 1 wheel weight on each side** + 3 weights* |

1580 Front Mower |

0 |

1* |

0 |

1* |

NA NA |

NA |

0 |

NA |

2* |

0 |

|

1585 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

NA |

NA |

NA |

1* |

NA |

6* |

Wide track 1 wheel weight on each side** + 3 weights* |

1575/1585 Cab models: Rim design allows for tire assembly to be mounted in two different configurations, a narrow track or wide track width, to meet ballast requirements. |

|||||||||||

* 42-lb (19-kg) (UC13263) Quik-Tatch weight (requires TCB10303, rear weight mounting kit). |

|||||||||||

** 50-lb (23-kg) front wheel weight(s) required (installation requires BM18101, mounting hardware kit). |

|||||||||||

NA - Not recommended for use on front mower. |

|||||||||||

NOTE: Ballast requirements may change. Always refer to the implement owner's manual for the appropriate ballast requirements. |

|||||||||||

Key Specs

| Engine Manufacturer/model | 3TNV88C |

|---|---|

| Engine Power | Gross PS: 37.4 hp 27.5 kW |

| Fuel tank capacity | 16 U.S. gal. 60.6 L |

| Mower deck Size | 60 or 72 in. 152, 183 cm |

| Blade tip speed | 18,000 fpm 5,486 m/min |

| Transmission | Hydrostatic full time 4WD, on-demand |

| Speed range | 0-12 mph 0-19.3 km/h |

| Drive wheels | 23x10.5-12 |

| Caster wheels | Flat free, 11x4-5 |

| Warranty | 24 months |

Engine

| Manufacturer/model | 3TNV88C |

|---|---|

| Power | Gross PS, 37.4 hp 27.5 kW |

| Rated engine rpm | 3,000 rpm |

| Cylinders | Three |

| Displacement | 100.2 cu in. 1.64 L |

| Maximum torque | At 1,950 rpm: 80.4 lb-ft 109 Nm |

| Injection | Direct |

| Fuel type | Diesel (B20 compatible) |

| Fuel tank capacity | 16 U.S. gal. 60.6 L |

| Cooling | Liquid |

| Cooling capacity | 10 U.S. qt 9.5 L |

| Air cleaner | Dual element dry type |

| Air restriction indicator | Standard |

| Charging system | Automotive type |

| Alternator, amp | 95 amp |

| Battery | 12 V |

Drivetrain

| Transmission | Hydrostatic full time 4WD, on-demand |

|---|---|

| Speed and direction control | Two-pedal foot |

| Cruise control | Optional |

| Hi/Lo range | No, single speed transmission |

Travel speed

| Speed range | |

|---|---|

| Hi forward | 0-12 mph 0-19.3 km/h |

| Lo forward | |

| Hi reverse | 0-5 mph 0-8 km/h |

| Lo reverse | |

| 4-wheel drive | |

| Differential lock | |

| Final drives | |

| PTO | |

| PTO clutch | |

| PTO drive output |

Hydraulics

| Type | Open center |

|---|---|

| Pump capacity | 5.1 U.S. gpm 19.3 L/min |

| Spool valve | Front lift, standard |

| Lift cylinders | Two |

Steering

| Type | Hydraulic cylinder |

|---|---|

| Turns lock-to-lock | 2 maximum, 1.5 minimum |

Brakes

| Type | Internal wet disk |

|---|---|

| Individual turn brakes | Standard |

| Master brake | Standard, locking |

Buyer's notes

| Warranty | 24 months |

|---|

Tires

| Drive wheels | 23x10.5-12 |

|---|---|

| Steering | 18x8.5-10 |

Weight transfer

| Type | Optional hydraulic |

|---|

Dimensions

| Wheelbase | 49.2 in. 125 cm |

|---|---|

| Ground clearance | 6.5 in. 16.5 cm |

| Length | Less mower deck: 86.7 in. 220.2 cm |

| Overall width | Narrow Width 23x10.5 tires: 51.8 in. 131.6 cm Wide Width 23x10.5 tires: 60.3 in. 153.2 cm |

| ROPS | Factory installed ComfortCab |

| ROPS certification | Two-post: OSHA 1928; Canadian Std.: CSA-352 Four-post: SAE J2194; EU Standard: 86/298/EEC; ISO 21299:2009 |

| Overall height with ROPS | With cab: 83.9 in. 213 cm |

| Overall height with ROPS folded | |

| Shipping weight | Net weight without mower or fuel: 2,436 lb 1,105 kg |

Mower decks

| Construction | One-piece stamped steel; 7-Iron PRO |

|---|---|

| Deck thickness | 7 gauge 0.180 in. 4.6 mm |

| Size | 60 or 72 in. 152 or 183 cm |

| Deck offset | Yes |

| Cutting height | 1-6 in. 2.54-15.24 cm |

| Belt tensioning | Spring loaded |

| Blade tip speed | 18,000 fpm 5,486 m/min |

| Caster wheels | Type Flat free Size 11x4-5 |

| Front anti-Scalp rollers | Yes, gauge wheels |

| Rear anti-scalp rollers | Yes, gauge wheels |

| Shipping weight |

Mower deck (rear discharge)

| Cutting width | 62, 72 in. 157, 183 cm |

|---|---|

| Cutting height | 1-6 in. 2.54-15.24 cm |

| Caster wheels | Type Flat free Size 11x4-5 |

| Shipping weight |

Additional information

| Date collected | 1-Oct-22 |

|---|

Central Jersey Equipment is committed to your privacy. For more information view our Privacy Statement

-

Columbus

Columbus

2885 Route 206 South, Bldg. 4

Columbus, NJ 08022

(609) 288-6637

Get Directions

-

Elmer

Elmer

670 Route 40

Elmer, NJ 08318

(856) 358-2880

Get Directions

-

Marlboro

Marlboro

65 State Route 34 unit 1

Marlboro, NJ 07746

(732) 938-6677

Get Directions

-

Hammonton

Hammonton

100 US Route 206

Hammonton, NJ 08037

(609) 704-9440

Get Directions

-

Columbia

Columbia

228 Route 94

Columbia, NJ 07832

(908) 362-6916

Get Directions

Copyright © 2017 - 2025 Site by EquipmentLocator.com AM

Call Us

Call Us