- Home

- Used Equipment

- Equipment Packages

- Small Tractors

- All Product Lines

- Departments

- Company Profile

- Parts Online

- Contact Us

- John Deere Specials - Save Some Green

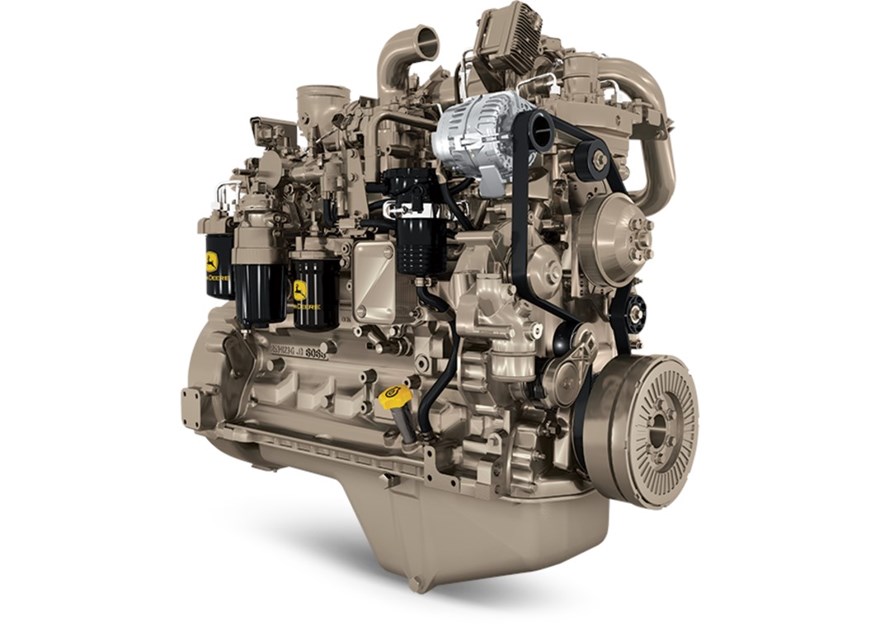

6090CG550

9.0L Generator Drive Engine

- PowerTech™ PSS

- Standby: 273-326 kW (366-437 hp)

@ 1500-1800 rpm - Prime: 248-297 kW (322-398 hp)

@ 1500-1800 rpm - Dual frequency available

-

Get a Quote

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Send to a Friend

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

-

Share

Features

Stage V.

John Deere has billions of hours of field experience with off-highway diesel engine technologies and launched many of its engines ahead of EPA and EU deadlines, and is ready to meet Stage V emissions regulations using our proven diesel particulate filter (DPF) solutions. In most cases, OEM customers currently using a John Deere engine with a diesel particulate filter (DPF) won’t have to re-engineer machine design to meet the requirements of Stage V regulations. Our engineers continue to employ a global network of technical resources and the latest technology to lower emissions while improving performance and fluid efficiency.

Series turbocharger

- Air is first drawn into the low-pressure turbocharger and compressed to a higher pressure. The compressed air is then drawn into the high-pressure turbocharger, where the air is further compressed. The high-pressure air is then routed through a charge air cooler and into the engine's intake manifold. By splitting the work between two turbochargers, both can operate at peak efficiency and at slower rotating speeds — lowering stress on turbocharger components and improving reliability. Series turbocharging delivers more boost pressure than single turbocharger configurations, which results in higher power density, improved low-speed torque, and improved high altitude operation.

Exhaust filters

- This system is the Best Available Control Technology (BACT) for particulates that delivers premium block load acceptance characteristics, utilizing a catalyzed exhaust filter that contains a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF). The DOC reacts with exhaust gases to reduce carbon monoxide, hydrocarbons, and some particulate matter (PM). The downstream DPF traps and holds the remaining PM. Trapped particles are oxidized within the DPF through a continuous cleaning process called passive regeneration. Passive regeneration occurs during normal operating conditions when heat from the exhaust stream, and catalysts within the exhaust filter, trigger the oxidation of the trapped PM. If passive regeneration cannot be achieved due to low temperature, load, or speed, then PM is removed using active regeneration — an automatic cleaning process controlled by the exhaust temperature management system.

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing NOx.

Selective catalytic reduction (SCR)

- John Deere engines feature an SCR system that utilizes a urea-based additive, sometimes referred to as diesel exhaust fluid (DEF) to meet Stage V emission standards. A chemical reaction in the SCR catalyst converts urea and NOx emissions into nitrogen and water vapor.

High-pressure common-rail (HPCR)

- The HPCR fuel system provides variable common-rail pressure and high injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in excellent low-speed torque and transient response.

Compact size

- Lower installed cost

- Mounting points are the same as previous engine models

John Deere electronic engine controls

- Faster engine control unit (ECU) manages both the engine and the aftertreatment

- Premium software option integrates with equipment or vehicles to reduce engineering and installation costs

Big-engine durability

- Replaceable (wet) cylinder liners

- Single-piece steel piston with oil-cooling gallery

- Up to 500-hour oil change

- Gear-driven water pump

Additional features

- Engine or remote mounted Fuel filters

- Gear-driven auxiliary drives

- Self-adjusting poly-vee fan drive with optional variable-speed fan

- Electric fuel transfer pump with “auto-prime” feature

- Full flow engine-mounted oil cooler

Emissions Certifications

| CARB | |

|---|---|

| EPA Final Tier 4 | |

| EU Stage V |

General engine data

| Model | 6090CG550 |

|---|---|

| Number of cylinders | 6 |

| Displacement-- L (cu in) | 9.0 (549) |

| Bore and Stroke-- mm (in) | 118.4 x 136 (4.7 x 5.4) |

| Compression Ratio | 16.0 : 1 |

| Engine Type | In-line, 4-cycle |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Length - mm (in) | 1326 (52.2) |

| Width-- mm (in) | 879 (34.6) |

| Height-- mm (in) | 1266 (49.8) |

| Weight, dry - kg (lb) | 1096.8 (2418) |

ATD

| DOC/DPF | Size 5 Size 6 Size 7 |

|---|---|

| SCR Catalyst | Size 5 Size 6 Size 7 |

Performance data range

| Hz (rpm) | 60 ( 1800 ) 50 ( 1500 ) |

|---|---|

| Generator Efficiency % | 93 93 |

| Power Factor | 0.8 0.8 |

| Engine power - Prime kW | 248-297 248-277 |

| Engine power - Prime hp | 322-398 322-371 |

| Engine power - Standby kW | 273-326 273-304 |

| Engine power - Standby hp | 366-437 366-407 |

| Rated Fan Power - kW | 13.7-16.3 13.7-15.2 |

| Rated Fan Power - hp | 18.4-21.8 18.4-20.4 |

| Calculated generator set output - Prime kWe | 218-261 218-243 |

| Calculated generator set output - Prime kVA | 273-326 273-304 |

| Calculated generator set output - Standby kWe | 241-288 241-269 |

| Calculated generator set output - Standby kVA | 301-360 301-336 |

Central Jersey Equipment is committed to your privacy. For more information view our Privacy Statement

-

Columbus

Columbus

2885 Route 206 South, Bldg. 4

Columbus, NJ 08022

(609) 288-6637

Get Directions

-

Elmer

Elmer

670 Route 40

Elmer, NJ 08318

(856) 358-2880

Get Directions

-

Marlboro

Marlboro

65 State Route 34 unit 1

Marlboro, NJ 07746

(732) 938-6677

Get Directions

-

Hammonton

Hammonton

100 US Route 206

Hammonton, NJ 08037

(609) 704-9440

Get Directions

-

Columbia

Columbia

228 Route 94

Columbia, NJ 07832

(908) 362-6916

Get Directions

Copyright © 2017 - 2025 Site by EquipmentLocator.com AM

Call Us

Call Us