- Home

- Used Equipment

- Equipment Packages

- Small Tractors

- All Product Lines

- Departments

- Company Profile

- Parts Online

- Contact Us

- John Deere Specials - Save Some Green

210 P-Tier

Mid-Size Excavator

- Net Power: 119 kW (159 hp)

- Max. Digging Depth: 6.67 m (21 ft. 11 in.)

- Operating Weight: 23 560 kg (51,940 lb.)

- Build Your Own

-

Get a Quote

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Send to a Friend

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

- Download Grade Management Brochure

-

Share

Features

Heavy configuration option

210 P with Heavy Duty (HD) boom and counterweight

210 P with Heavy Duty (HD) boom and counterweight

Overview

Get more out of your 21 metric ton (46,297 lb) excavator with the new heavy duty boom and heavy counterweight option. These options combined add weight to the machine while still maintaining the powerful 6.8L engine to better compete in the upper limits of the popular 21-24 metric ton (46,297-52,910 lb) size class.

- Heavy duty one piece 5730 mm (18 ft 8 in.) boom

- Heavy counterweight adds an additional 589.7 kg (1300 lb) to the rear of the machine for excellent stability

- Heavy duty bucket link

- Additional track guide (total 3 per side)

Improved front joint durability

Central lubrication at arm tip

Central lubrication at arm tip

Two-piece front pipe clamping

Two-piece front pipe clamping

Internal view of central lubrication grease path

Internal view of central lubrication grease path

Overview

P-Tier updates build on the proven G-series design. Take front joint durability to new levels compared to G-series.

- Grease point at arm tip for easy greasing and extended uptime

- Better torque retention at the clamp reduces the likelihood of front hydraulic pipes moving

- Redesigned boom foot bushings improve durability

Quickly change attachments with integrated hydraulic coupler ready option

Hydraulic coupler ready option

Hydraulic coupler ready option

Overview

Factory installed hydraulic plumbing all the way to the end of the arm. Coupler controls integrated into a switch in the cab. Quick and efficient coupler installation. Popular in the underground segment, couplers allow excavators to efficiently switch attachments and get more productive working hours each day.

- Ease of installation – pin on the coupler, connect the hydraulics, get to work

- Compatible with multiple coupler manufacturers (see dealer for details)

Additional Details

Coupler control switch on left side pilot tower

Coupler control switch on left side pilot tower

SmartGrade™ technology

SmartGrade™ excavator

SmartGrade™ excavator

Overview

SmartGrade™ technology is changing construction and revolutionizing the way you will run your operation. In the past, workers were prone to mistakes and required frequent grade checks to ensure the precision of their work. Now, with guidance and control to increase their speed and accuracy, operators of all skill levels can benefit from these new tools.

SmartGrade™ technology improves productivity with fewer mistakes and less downtime.

- Quickly and confidently achieve grade with fewer periodic grade checks.

- Improve accuracy and time to get to final grade for operators of all skill levels.

- Machine is equipped with elevation, eliminating the need for benchmarking or catching a laser.

- Upgrade kits allow you to adopt technology at your own pace.

No loss of investment and no need to purchase a new machine, you have precise accuracy when the time is right.

John Deere knows how over-grading, understaffing, and lack of time add up to rework. Especially given that the jobsite is never the same two days in a row. That is why our flexible grade-management tools are engineered to minimize rework or avoid it altogether while obstacle Intelligence uses cameras, radar, and machine learning to protect anyone in close proximity. Machine monitoring and connected support keep you updated with machine and fleet performance to boost productivity and keep your business humming.

Eliminate rework

- Maintains set blade or bucket angle for precise grading while operator controls machine position.

- Monitors elevation and slope information on any terrain.

- Fewer passes regardless of operator experience level.

Improve jobsite safety

- Rear camera monitors obstacles on the back side of the machine.

- Mirror-mounted cameras provide a wider field of view than conventional mirrors.

- In-cab display shows the operator potential hazards in close proximity.

Counteract labor shortages

- Communicates with other equipment on site for greater overall productivity.

Increase efficiency

- Remote diagnostics give real-time updates on machine service intervals and can prevent service visits to the jobsite.

- Machine telematics are shared with our monitoring center and your dealer via the cloud.

- Track key metrics, from individual machine productivity to total job progress.

Whatever you are up against, we have the tools to help you get the job done.

SmartGrade™ excavator

SmartGrade™ excavator

Up to 7% improved fuel economy

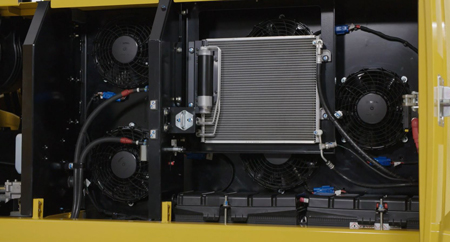

Electronic cooling fans

Electronic cooling fans

Overview

At John Deere, we understand that jobsite conditions are tough and operating costs can drain your business. With new features now included on our 210, 250, and 300 P excavators, your fuel economy can improve by up to 7%. This not only helps your operation run more smoothly but can also help you save both time and money.

These new features have improved fuel economy:

- Reduce engine load with electric on-demand cooling fans.

- Individually serviceable fans with four bolts and one connector to remove and replace.

- In-line aftertreatment for reduced restriction and system complexity.

- Increased front piping diameter reduces hydraulic restriction, positively impacting fuel consumption.

With improved fuel economy, you can experience less downtime and lower daily operating costs.

Work confidently via optional cameras and lighting

Right, rear, and left cameras with additional light-emitting diode (LED) surround lighting

Right, rear, and left cameras with additional light-emitting diode (LED) surround lighting

Overview

Optional right, rear, and left camera system with additional light-emitting diode (LED) surround lighting work together to provide the operator enhanced 270 degree visibility around the machine. All integrated into the main monitor.

Benefits

- Work confidently with enhanced visibility even in low light conditions

- Powerful LEDs cast a pool of light surrounding 270 degrees of the sides and rear of the machine. Cameras display surroundings to the operator in the main monitor

- LED front work lights and rear camera are still standard equipment

DRIVELINE

| Emission Rating | Tier 4 |

|---|---|

| Engine Manufacturer | John Deere Power Tech |

| Number Of Cylinders | 6 |

| Displacement, ltr (Inches³) | 6.8 (415) |

| Rated speed, rpm | 2000 |

| Engine Output - Net, kW (hp) | 119 (159) |

| Number Of Carrier Rollers - Each Side | 2 |

| Number Of Track Rollers - Each Side | 7 |

| Track Shoe Width, mm (inches) | 800 (32) |

DIMENSIONS

| Transport Length Mono Boom, mm (ft/in) | 9530 (31 ft 3 in) |

|---|---|

| Transport Height - Maximum, mm (ft/in) | 3010 (9 ft 11 in) |

| Overall Undercarriage Width, mm (ft/in) | 3020 (9 ft 11 in) |

| Track Length On Ground, mm (ft/in) | 3350 (11 ft ) |

| Overall Undercarriage Length, mm (ft/in) | 4170 (13 ft 8 in) |

| Tailswing Radius, mm (ft/in) | 2890 (9 ft 6 in) |

| Ground Clearance, mm (inches) | 450 (17.72) |

| Width over fixed tracks, mm (ft/in) | 3020 (9 ft 11 in) |

| Track Gauge, mm (ft/in) | 2220 (7 ft 3 in) |

| Digging Reach - Mono Boom, mm (ft/in) | 9920 (32 ft 7 in) |

| Ground Level Reach - Mono Boom, mm (ft/in) | 9750 (32 ft ) |

| Dig Height - Mono Boom, mm (ft/in) | 10040 (32 ft 11 in) |

| Dump Height - Mono Boom, mm (ft/in) | 7180 (23 ft 7 in) |

| Dig depth - 2.44m / 8'ft flat bottom, mm (ft/in) | 6500 (21 ft 4 in) |

| Dig Depth - Mono Boom, mm (ft/in) | 6670 (21 ft 11 in) |

| Standard Arm, mm (ft/in) | 2910 (9 ft 7 in) |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 403 (106.5) |

|---|---|

| Hydraulic Tank, ltr (gallons (US)) | 135 (35.7) |

| Number Of Batteries | 2 |

| Voltage, V | 24 |

PERFORMANCE

| Ground Bearing Pressure, kPa (PSI) | 37.7 (5.47) |

|---|---|

| Swing Speed, rpm | 13.3 |

| Swing Torque, kNm (lbf / ft) | 68.9 (50662) |

| Travel Speed - High, kph (mph) | 5.5 (3.4) |

| Tractive Force, kN (lbf) | 202.9 (45636) |

| Arm Tearout, kN (lbf) | 114 (25628) |

| Bucket Breakout, kN (lbf) | 158 (35520) |

| Gradeability, % | 70 |

| End lift - 7.5m Reach, kg (lbs) | 4420 (9520) |

| Side lift - 7.5m Reach, kg (lbs) | 2730 (5860) |

| Total Flow, lt/min (gallons (US) / min) | 424 (112) |

| Bucket Pressure, bar (PSI) | 343 (4975) |

| Boost Pressure, bar (PSI) | 380 (5511) |

WEIGHTS

| Operating Weight, kg (lbs) | 23161 (51061) |

|---|

Central Jersey Equipment is committed to your privacy. For more information view our Privacy Statement

-

Columbus

Columbus

2885 Route 206 South, Bldg. 4

Columbus, NJ 08022

(609) 288-6637

Get Directions

-

Elmer

Elmer

670 Route 40

Elmer, NJ 08318

(856) 358-2880

Get Directions

-

Marlboro

Marlboro

65 State Route 34 unit 1

Marlboro, NJ 07746

(732) 938-6677

Get Directions

-

Hammonton

Hammonton

100 US Route 206

Hammonton, NJ 08037

(609) 704-9440

Get Directions

-

Columbia

Columbia

228 Route 94

Columbia, NJ 07832

(908) 362-6916

Get Directions

Copyright © 2017 - 2025 Site by EquipmentLocator.com AM

Call Us

Call Us