- Home

- Used Equipment

- Equipment Packages

- Small Tractors

- All Product Lines

- Departments

- Company Profile

- Parts Online

- Contact Us

- John Deere Specials - Save Some Green

540M

Loader

- Superior strength and visibility

- For heavy-duty chores

- Parking stands are integrated on the loader

- Build Your Own

-

Get a Quote

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Send to a Friend

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

-

Share

Features

Single-point hydraulic connection saves time

Single-point hydraulic connection on 6 Series Tractors (closed position)

Single-point hydraulic connection on 6 Series Tractors (closed position)

The H310 Loader can be ordered with a single-point hydraulic connection that also incorporates the connection point for any electrical needs. To disconnect the hydraulic connection between the loader and the tractor, it is necessary to relieve the hydraulic system oil pressure on the tractor.

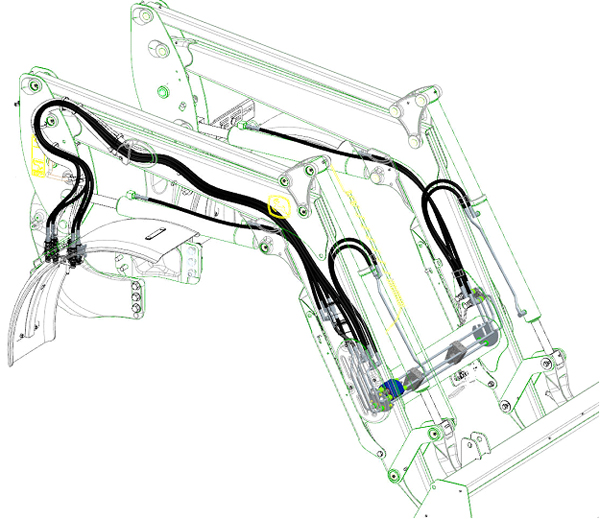

Concealed oil lines improve appearance and reduce damage

Concealed oil lines through boom arm

Concealed oil lines through boom arm

Oil lines routed through the boom arm

Oil lines routed through the boom arm

Oil lines routed through the torque tube

Oil lines routed through the torque tube

Over time, increased width in tractor hoods have caused issues with available space for running traditional oil lines of a loader along the boom, making them more susceptible to damage.

To improve this situation, the oil lines have been routed through the boom arm and the torque tube, improving line protection and the appearance of the loader.

Loader removal (parking) made easy

Parking stands

Parking stands

John Deere loaders are easily removed and reinstalled on tractors without tools. The parking system allows removing or attaching the loader to the tractor in minutes without the need for tools.

To remove or park the loader, apply slight down pressure to the loader boom with the bucket dumped at approximately a 30-degree angle. With the tractor in park, lower the parking stands and place the mast pins in the open position.

Removing or parking the loader

Parking stand in stored position

Parking stand in stored position

Removing parking stand

Removing parking stand

Mast pin in the closed position

Mast pin in the closed position

Rotating mast pin to the open position

Rotating mast pin to the open position

Utilizing the boom circuit with the tractor in neutral, rotate the mast forward until the mast has rotated past the pin location on the mounting frame by extending the lift cylinder. Now using the bucket circuit, roll back the bucket until the mast is removed from the pocket and will clear the tires.

Mast pin in the open position

Mast pin in the open position

With the tractor in park, shut the engine off and relieve the hydraulic pressure as indicated for the tractor (rotating the joystick). Disconnect or open the single-point hydraulic connector (or remove couplers if no single point is installed).

Disconnect/open single-point hydraulic connection

Disconnect/open single-point hydraulic connection

Disconnect/open single-point hydraulic connections

Disconnect/open single-point hydraulic connections

Store the loader half of the single-point connector or hoses, and back away from the loader.

Single-point hydraulics disconnected

Single-point hydraulics disconnected

Boom lockout for easy service

Hydraulic shut-off valve (open position)

Hydraulic shut-off valve (open position)

Hydraulic shut-off valve (closed position)

Hydraulic shut-off valve (closed position)

A hydraulic shut-off valve is included with the M & R-Series Utility & Ag Loaders to ensure the loader does not lower suddenly. For example, this allows the boom to be locked out when someone is required to be located under the loader boom for service work on the tractor. It should not be used for extended periods of time unless an appropriate support stand is also utilized.

Key Specs

| Maximum lift height (A) | 3578 mm 141 in. |

|---|---|

| Lift capacity at full height | Measured at pivot (U) 1373 kg 3027 lb |

| Boom breakout force | Measured at pivot (Y) 2671 kg |

| Bucket rollback force capacity | At ground-level line (ZZ) 3046 kg |

| Clearance at full height - bucket dumped (C) | 2538 mm 100 in. |

| Dump angle, degrees (E) | -74 degree (angle) |

| Rollback angle, degrees (G) | 42 degree (angle) |

Tractor

| Model | 6135E |

|---|---|

| Front tire | 14.9R24 |

| Rear tire | 18.4R38 |

| Front axle configuration | MFWD |

| Wheelbase | 2380 mm 94 in. |

| Pump capacity | 75.7 L/min 20 gpm |

| Rated pressure | 195 bar 2828 psi |

Loader

| Base weight | 1028.2 kg |

|---|---|

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | Materials 1850 mm Materials 73 in. |

| Bucket weight | 246 kg 542 lb |

| Lift capacity at full height | Measured at pivot (U) 1373 kg 3027 lb Measured at 800 mm ahead of pivot (V) 1481 kg |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 2015 kg Measured at 800 mm ahead of pivot (X) 1931 kg |

| Boom breakout force | Measured at pivot (Y) 2671 kgf Measured at 800 mm ahead of pivot (Z) 2325 kg |

| Bucket rollback force capacity | At maximum height (VV) 1636 kg At 59-in. (1500-mm) lift height (XX) 2986 kg At ground-level line (ZZ) 3046 kg |

| Dimensions | Maximum lift height (A) 3578 mm 141 in. At full height - bucket level(B) 3383 mm 133 in. At full height - bucket dumped (C) 2538 mm 100 in. |

| Overall length (I+F), ft (m) | 4.8 m 15.8 ft |

| Overall height in carry position (J) | |

| Digging depth (H) | 47 mm 1.9 in. |

| Reach | At maximum height (D) 1011 mm 39.8 in. At ground level - bucket level (F) 2426 mm 95.5 in. |

| Bucket angle | Dump angle, degrees (E) -74 degree (angle) Rollback angle, degrees (G) 42 degree (angle) Dump angle, ground -96 degree (angle) |

| Cycle times | Loader raise, seconds 3.4 seconds Loader lower, seconds 2.5 seconds Bucket dump, seconds 2.1 seconds Bucket rollback, seconds 2.1 seconds |

Additional information

| Date collected |

|---|

Central Jersey Equipment is committed to your privacy. For more information view our Privacy Statement

-

Columbus

Columbus

2885 Route 206 South, Bldg. 4

Columbus, NJ 08022

(609) 288-6637

Get Directions

-

Elmer

Elmer

670 Route 40

Elmer, NJ 08318

(856) 358-2880

Get Directions

-

Marlboro

Marlboro

65 State Route 34 unit 1

Marlboro, NJ 07746

(732) 938-6677

Get Directions

-

Hammonton

Hammonton

100 US Route 206

Hammonton, NJ 08037

(609) 704-9440

Get Directions

-

Columbia

Columbia

228 Route 94

Columbia, NJ 07832

(908) 362-6916

Get Directions

Copyright © 2017 - 2025 Site by EquipmentLocator.com AM

Call Us

Call Us