- Home

- Used Equipment

- Equipment Packages

- Small Tractors

- All Product Lines

- Departments

- Company Profile

- Parts Online

- Contact Us

- John Deere Specials - Save Some Green

RDF45

HydraFlex™ Draper

- Harvest crops as close as possible to the ground with the HydraFlex™ cutterbar

- Minimize grain loss with a two-speed center feed section

- Enable higher harvesting speed without sacrificing cut quality with a 4” double cut, dual drive, shaft driven cutterbar

- Get more done by eliminating header calibrations

-

Get a Quote

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Send to a Friend

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

- View Front End Equipment Brochure

-

Share

Features

Optimize feeding with a two-speed center feed section, increased feed drum torque, and center crop flow divider

Overview

Increase grain in the tank with a two-speed center feed section. A slow-speed setting softens the impact of crop fingers and drum flighting when engaging with crop. This ensures that easy-shelling crops like lentils and soybeans do not get thrown over the feeder house. Use the high-speed setting in canola or high-yielding cereals to prevent slug feeding while ensuring that the drum does not plug.

Benefits

- Experience less downtime during harvest related to unplugging the header, which allows for more harvesting time at the highest productivity levels.

- Higher feed drum torque is matched to the capacity of the combine to ensure optimal feed rates into the combine. Higher torque on the front feed drum allows operators to confidently harvest tough feeding crops like canola.

- Additionally, prevent underfeeding in light crops with the center crop flow divider. When not harvesting crop with the full width of the draper, the center crop flow divider prevents crop from skipping over the center feed section and going on the opposite draper belt.

Toolless shifting on the gearcase

Toolless shifting on the gearcase

Center crop flow divider

Center crop flow divider

Additional details

- The two-speed center feed section maintains a consistent ratio between the feed drum and center feed belt speed.

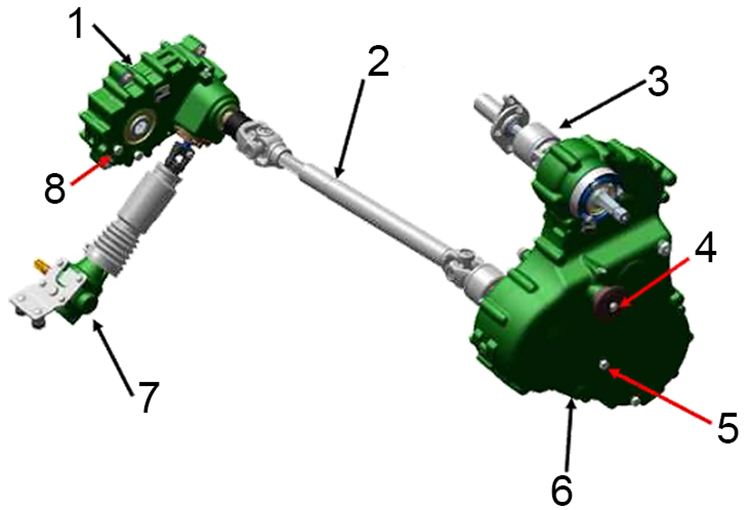

- Change center feed section speed with a toolless, two-speed, easy-shift handle on the gearcase to the left of the draper feeder house opening.

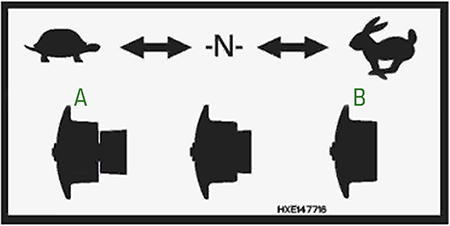

Two-speed center feed section (A is pulled out and B is pushed in)

Two-speed center feed section (A is pulled out and B is pushed in)

Parts of the two-speed center feed section

Parts of the two-speed center feed section

- Feed drum gearbox

- Center feed drive shaft

- Knife drive shaft

- Center feed speed control

- Oil check

- Main gearbox

- Center belt gearbox

- Oil check

|

Low speed |

High speed |

Feed drum |

200 rpm |

240 rpm |

Center feed belt |

1000 rpm |

1200 rpm |

|

RDF |

HDR |

Feed drum torque |

1217 lb-ft (1650 Nm) |

2109.4 lb-ft (2860 Nm) |

Center belt width |

70 in. (177.8 cm) |

79.1 in. (200.9 cm) |

Superior ground following with the HydraFlex™ draper system

Overview

Achieve superior ground following when harvesting in a wide range of terrains, crops, and conditions with RDF HydraFlex Draper Platforms. HydraFlex is an industry-exclusive hydraulic float system.

HydraFlex draper system floats with the terrain

HydraFlex draper system floats with the terrain

Benefits

- Float closely to the ground over changing conditions by controlling the cutterbar ground pressure from the cab – simply adjust the armrest knob to vary hydraulic pressure in the float arm hydraulic cylinders.

Hydraulic float arm

Hydraulic float arm

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Additional details

- The hydraulic float system features a 7.5-in. (19-cm) float range.

- To lock out the HydraFlex draper into rigid mode, the operator should increase the float pressure to maximum

Evenly feed canola and field peas into the feeder house with RDF top augers

Overview

Help bushy crops, especially heavy canola, feed evenly into the feeder house with an optional 18-in. (45.7-cm) top auger extending the full width of the draper.

RDF top auger

RDF top auger

Benefits

- With the crop tucked under the auger, the handoff to the center feed drum enables smooth and consistent feeding to the combine to ensure constant load.

- Achieve smooth headfirst feeding when auger speeds are running slightly faster than the belt speed.

Additional details

- This optional 18-in. (45.7-cm) hydraulically driven top auger has an easy speed adjustment at the right side of the platform.

- It is recommended for operation in bushy or high-volume harvesting conditions such as canola.

- Augers can be turned off for crops like lentils or wheat where they are not recommended.

Key Specs

| Cutterbar length | 13.72 m 45 ft |

|---|---|

| Knife drive | Double-cut, dual-drive, shaft-driven cutterbar: 10.2 cm 4 in. |

| Knife speed | X Series Combine: 520 cycles/min S-Series Combine: 490 cycles/min |

| Pickup reel operating speeds | 6-70 rpm |

| Draper belts speed control | Hydraulic from cab (side belts only) |

Platform

| Type | Rigid frame flexible cutterbar |

|---|

Cutterbar

| Type | Straight-line knife drive system Cutterbar vertical flex: 190 mm 7.5 in. |

|---|---|

| Length | 13.72 m 45 ft |

| Knife drive | Double-cut, dual-drive, shaft-driven cutterbar: 10.2 cm 4 in. |

| Knife speed | X Series Combine: 520 cycles/min S-Series Combine: 490 cycles/min |

| Cutterbar tilt | |

| Base skid shoe height | 3.8 cm 1.5 in. |

Pickup reel

| General | Two-piece, poly tine pickup reel with 8-in. (20-cm) tube |

|---|---|

| Number of slats | Six bat poly |

| Fingers | Nylon |

| Diameter | 106.7 cm 42 in. |

| Height control | Hydraulic |

| Speed control | Hydraulic |

| Reel lift | 72 cm 28.3 in. |

| Reel fore and aft | 35.9 cm 14.1 in. |

| Fore of the cutterbar | 40.6 cm 16 in. |

| Reel resume | Base |

| Reel reverse | Base |

| Operating speeds | 6-70 rpm |

| Operating speeds (54-in. reel) |

Slat reel

| Number of slats | |

|---|---|

| Diameter | |

| Height control | |

| Speed control | |

| Operating speeds |

Draper belts

| Width | Side belts: 101.6 cm 40 in. Center belts: 177.6 cm 70 in. |

|---|---|

| Belt depth | 101.2 cm 39.8 in. |

| Cleat height | 19.05 mm 0.75 in. |

| Operating speed | Side belts (variable): 1-3.5 m/s 3.3-11.5 fps Center belts: 211 m/min 692 fpm Low-speed center belt (fixed): 4.2 m/s 13.8 fps High-speed center belt (fixed): 5.1 m/s 16.7 fps |

| Speed control | Hydraulic from cab (side belts only) |

| Center belt reverse | Base |

Feed drum

| Diameter | 414 mm 16.3 in. |

|---|---|

| Feed drum fingers | Heavy-duty and round with breakaway notch and retainer Diameter: 16 mm 0.625 in. |

| Number of fingers | 21 |

| Auger finger platform | Triple chevron, retracting |

| Finger reach | 152 mm 6 in. |

| Drum/auger reverse | Base |

| Operating speed | Low speed: 200 rpm High speed: 240 rpm |

| Center cleanout door | Base |

Header height sensing

| Type | Electrohydraulic |

|---|---|

| Header height sensing on the ground | Base |

| Header height sensing off the ground | Optional: four sensors |

Top auger

| Type | Optional: hydraulic drive |

|---|---|

| Fingered augers | |

| Size | 45.7 cm 18 in. |

Dimensions

| Platform length | 14.6 m 47.9 ft |

|---|---|

| Overall operating depth | With dividers: 2.74 m 9 ft |

| Transport width, field position | 14.6 m 47.9 ft |

| Transport width on wheel, less dividers | |

| Transport length, hitch extended |

Weight

| Approximate weight | 4437 kg 9782 lb |

|---|

Additional information

| Date collected | 15 June 2020 |

|---|

Central Jersey Equipment is committed to your privacy. For more information view our Privacy Statement

-

Columbus

Columbus

2885 Route 206 South, Bldg. 4

Columbus, NJ 08022

(609) 288-6637

Get Directions

-

Elmer

Elmer

670 Route 40

Elmer, NJ 08318

(856) 358-2880

Get Directions

-

Marlboro

Marlboro

65 State Route 34 unit 1

Marlboro, NJ 07746

(732) 938-6677

Get Directions

-

Hammonton

Hammonton

100 US Route 206

Hammonton, NJ 08037

(609) 704-9440

Get Directions

-

Columbia

Columbia

228 Route 94

Columbia, NJ 07832

(908) 362-6916

Get Directions

Copyright © 2017 - 2025 Site by EquipmentLocator.com AM

Call Us

Call Us